DTF printing: the hottest digital textile printing technology!

Screen printing or digital textile printing? Transfer paper ironing or direct T-shirt printing? What if there was a new digital printing technology which would allow you to take advantage of these printing methods without the compromises? With DTF printing, you can create prints that can be ironed onto textiles resulting in a durable, vivid-colored and a flexible print, which are cost-effective in both small and large volume production!

What is DTF? Let's talk about the basics!

DTF is the abbreviation of Direct To Foil. DTF printing is an incredibly innovative, new solution that combines industrial screen printing and digital printing, keeping their advantages while eliminating their disadvantages!

A layer of special hot-melt adhesive powder must be applied to the ink printed on the transparent DTF film, and then fixed by some kind of heat treatment. It results in an adhesive material from which the print could be transferred (even later, not necessary in this work process) to the surface of textiles – such as T-Shirts – with a heat press or special DTF heat treatment unit.

If you're not planning to print T-Shirts and textiles as a hobby, but rather as a profitable business, then you will need the following tools and supplies for DTF printing:

- Digital printer

- Heat treatment unit

- DTF adhesive powder

- DTF PET foil

- Heat press

| We do not deal with converted Epson L1800 printers. Why? If you choose this path, it is guaranteed that you will have countless technical problems, excruciatingly slow print speed and spending a lot of time on professional forums for help requests. Even if the L1800 DTF printer works, you will realize at the first serious order that your business cannot grow with this level of performance. Surely you don't want to belong to this group. |

How does DTF technology work?

You can print the image content with the digital printer directly on the DTF film. With roll-to-roll DTF systems, the DTF adhesive powder is applied and fixed on it in the automatic powdering-heat treatment unit. With desktop DTF systems, the DTF adhesive powder needs to be applied manually to the print on the DTF film and then fixed in a desktop heat treatment machine. The former is automatic and fast, the latter is a slower, manual process, but the printer is cheaper. The finished, heat-treated print can be just an A4 color photo, a text, or even thousands of small company logos or emblems. You can iron these ready-made stickers to the surface of your chosen textile in a heat press.

Even for screen printing shops!

The industrial screen printing technology is primarily suitable for serving medium and large volume orders. DTF is an excellent alternative solution if you want to print T-Shirts with screen printing quality and durability on colored textiles at low cost and with a productive digital process. DTF technology combines the advantages of screen printing with the flexibility of digital reproduction. Even a few A4 prints can be economically produced with variable image content and without additional tool costs. In fact, screen printers already knew the above-mentioned adhesive powder decades ago, DTF technology is the digitized version of this hot-melt transfer technology.

What type of DTF printer should you choose?

When choosing a printer, you should decide what level of productivity you expect from your DTF system and what kind of budget you have for the investment. If you run a start-up small business, or even a small workshop at home, then choose our desktop DTF printer, or an automatic roll-to-roll system with compact 30cm print width to avoid the manual process. If the goal is even more productive industrial textile printing, then choose our industrial roll-to-roll DTF systems with up to 60 cm print width.

What kind of DTF printers can you choose from?

For masochists, self-haters and those who have a lot of unnecessary free time which they want to devote to printer maintenance and extremely slow print times.

Various types of printers from many brands are suitable for DTF printing. Due to the initial success of DTF printing, several large manufacturers – such as Roland or Mimaki – have quickly relabeled their old models as DTF printers. They are stable, high-quality printers, which are now able to print DTF ink but that's about it. They usually have low printing speed, and more importantly, there is no built-in solution for applying and fixing the adhesive powder after printing. Therefore they are not a complete DTF system, but you should be looking for a DTF system, since a printer alone isn't enought to execute DTF printing on textiles.

This excellent alternative fills the gap between cheaper desktop DTF printers and the fully automatic industrial roll-2-roll DTF systems. The small format roll systems provide an automatic process similar to the industrial roll-to-roll DTF systems (automatic powdering and heat fixing after printing), but with a slightly slower printing speed and a width of 30 cm instead of 60 cm (the length can be more, since it is a roll). This can be an optimal solution for a smaller workshop!

Wide format roll-to-roll systems are undoubtedly the most popular DTF systems. DTF technology started to become successful with this type of DTF printing-heat-treatment system.

The advantage of a large-format DTF printer is that you can economically place the graphics on a 60 cm wide roll DTF film in the printing software, and then print it at a productive speed. After printing, a fully automatic unit performs the precise application of the adhesive powder, shakes off excess dust around the print on the film, heat fixes the adhesive (melts the powder onto the ink), and then the final winding.

Advantages of DTF printing

- Durable and flexible print

- Suitable for both cotton and synthetic textiles

- Great color gamut and saturation

- For white, colored and black materials

- Print without background without cropping

- Can be washed in machine

- Also great for screen workshops without tool costs

- Cost-effective

DTF PET film

DTF PET film

Special transfer foil, specifically designed for DTF printing. This is where you print first, which then will be transferred to the surface of the textile. Depending on the needs of the printer, you can choose from different sizes of sheet or roll films. There are also types with surface treatment on one or both sides. The advantage of the latter is that more layers receive the paint and it is less sensitive to humidity. This way, the print looks better on it, is less likely to slip in the printer, and can be removed immediately after heat treatment, while still warm.

DTF ink

DTF ink

The DTF ink is printed on the printable, transparent PET film. This digital textile ink is applied to the surface of the textile with the adhesive powder by the heat press. DTF printers – in addition to the basic printing CMYK colors – also contain white ink, so that you can print on colored or black T-Shirts as well! You can find several Chinese inks in the range of distributors, but we recommend our DTF ink from one of the world's leading brands: INKTEC. Their ink guarantees reliable white and bright colors. While Chinese brands can vary in quality from shipment to shipment, INKTEC provides consistent quality, to which we also provide ICC color profiles, to make sure your printed colors are spot-on.

DTF adhesive powder

DTF adhesive powder

The DTF adhesive powder is applied in a dry state to the surface of the print which is still wet, so it only sticks to the printed area. The white- or black-colored adhesive powder provides a base surface for your print, and since it only sticks to the printed area, the final print on the T-Shirt won't have a background. The powdered film must be heat-treated, so that it would melt and then solidify during heat fixing to be suitable for further processing. It is important to know that during manual powdering (with desktop DTF printers) you have to shake off the excess dust from the foil that has not sticked to the paint, otherwise it will create a thicker surface on the T-Shirt and results in printing mistakes. This is also why fully automatic DTF systems are preferable.

A must-have: DTF RIP software!

A must-have: DTF RIP software!

Many Chinese DTF printers are supplied with low-quality Acrorip, and sometimes even non-genuine, broken RIP software. The printer can still be used this way, but if you want truly stable printing, more economical ink costs, more functions, easier handling and more beautiful colors, then you should choose the professional DTF RIP softwares, which were specially developed for the roll-to-roll DTF systems we sell.

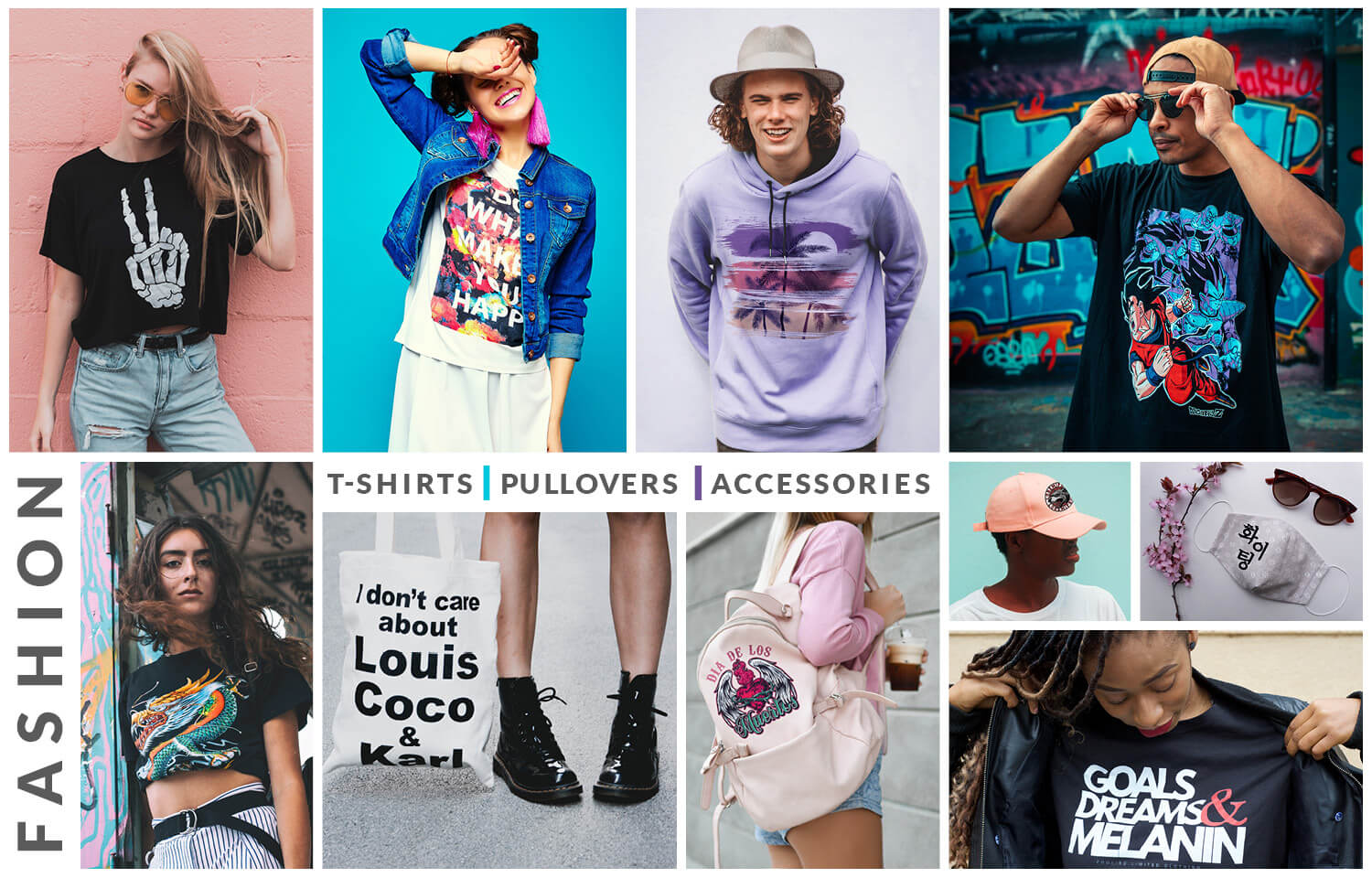

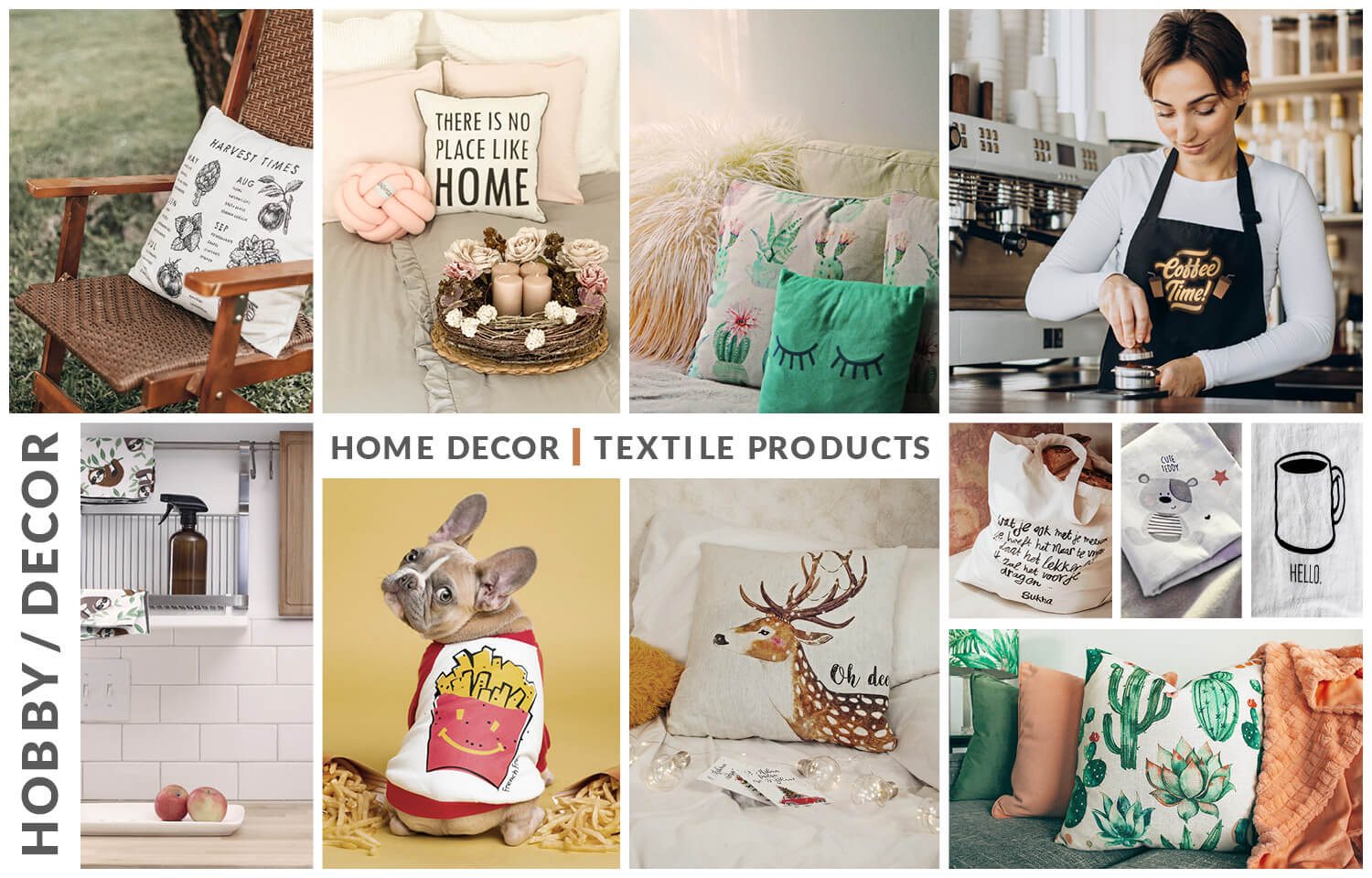

What type of products could be produced with DTF printing?

A wide range of unique textile products could be produced by the new Q0-DTF printer whether you are in the fashion or the home decor industry. T-Shirts, pullowers, jackets, baseball caps, aprons, bags, throw pillows and many more smaller sized textile products could be personalized with it. The following are just some examples:

Choose from our professional DTF systems!

By continuous testing, we have put together professional and well-coordinated DTF systems for you, whether your aim is desktop or wide-format printing. You could see our constantly expanding range by clicking on this link.

| Would you like to try it? Come to our showroom, where you can see in person how the technology works, and our expert colleague will help you with personalized advice. |